-40%

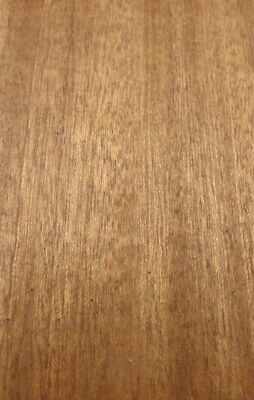

Wood veneer application scraper tool for paper and wood backed veneer products

$ 10.56

- Description

- Size Guide

Description

Wood veneer scraper application tool for lamination of wood veneer products. This is the ideal tool to scrape down and apply pressure to backed wood veneer sheet products. It also spreads and evens out the contact cement. You can use something similar, but this is the best way to do it. Make sure to file off any sharp edges so you do not cut the veneer.Trust the experience, knowledge, and reputation that has served the wood industry and novices since 1995.

Visit My eBay Store: JSO Wood Products

We have all kinds of wood veneer products. Raw, backed, and edgebanding!

Application Instructions

A stiff scraper should be available at the start. Most contact cements work fine.

Both flammable and water-based are satisfactory. Roller or brush grades seem to work better than faster drying spray grades.

You should have a supply of bare, hardboard separator strips 1/8" thick hardboard or similar to completely cover the contact cement. At the very least two separators, half the width of the substrate is required. Don't attempt to lay wood veneer without having all the contact cement surface. Once contact cement surfaces grab, it will be too late to move the sheet.

A. All open, hungry surfaces like Lauan, or Oak plywood will always require two coats of contact cement.

B. Tight faced surfaces like Hardboard, or M.D.F. may allow one coat.

Be generous with contact cement and aplly as smooth as possible. Coat both surfaces. If you spray apply the contact cement, do not apply dry, scant, open web pattern. 100% so no voids are left. Make certain you honor manufacturer's instructions as to open time. Wood expands across its grain in the presence of humidity. Un-mounted sheets of wood veneer left lying about may take on moisture making application difficult.

1. Make initial contact down the centerline.

2. Grasp the "east" flap.

3. Pull it taut. Stretch it so as to remove fullness and fluff.

4. Lower the tightly stretched flap as an assistant moves the separator strip away from the center line.

5. Using the wood veneer tool only scrape hard to tightly join the two glue lines. Use your body weight + both hands. This makes for maximum pressure.

Ridges (Ex. #1). This type failure occurs when the contact cement is rushed and the two surfaces have been put together too early. The contact cement is still damp and allows the veneer to expand across the grain to form ridges in the grain direction and generally all across the face. Allow more time for the contact cement to dry. Check for rubbery "legs" if the veneer must be peeled off. This indicates cement was too damp when surfaces were put together.

Bubbles (Ex. #2) This type failure results from using hammer blocks and/or palms and fingers. High humidity will cause poorly bonded wood to expand. The force of expansion occurs in the weakest bonded areas and bubbles pop-up. If bubbles won't stay down not enough cement was applied in the first place.

Helpful Hint No. 1: The use of a warm iron (set between wool and cotton) may reactivate the contact cement and put bubbles down tight if enough contact cement was applied in the first place. If contact cement is too scant, bubbles will pop back up.

Helpful Hint No. 2: When you put the iron down on the veneer be sure to use a piece of grocery bag type Kraft paper to keep face clean. Keep the iron in motion so well bonded cement is not loosened. If veneer should come loose under heat then reheated and scrape hard until area cools down again.

Helpful Hint No. 3: The wood veneers used to make wood veneer sheets are very thin. Don't try to use any grit coarser than 150 avoid a sand block. Use your hands so your fingertips can "read" the surface. Remember water will act to expand wood. Weak glue lines may fail. Wood tries to expand when wet by finishing materials.

1. Apply contact cement smooth, not webby and spattery.

2. Apply full wet coat over 100% of both surfaces.

3. Apply two coats on plywood, or porous substrates.

4. Honor flash-off times set by cements manufacturing.

5. Scrape down to make contact nip. If you have used enough contact cement and scraped the wood veneer down tightly, nothing short of water soak should cause veneers to bubble or blister.

All wood has some tendency to expand across the grain when saturated with a liquid.

If you failed to apply 100% coverage contact cement you will have less than 100% results. If your glue line has been poorly made veneer will eventually expand across the grain and show ridges and/or bubbles.